The extrusion facility is only setup to anodize clear metallic gray. We will black anodize your tracks for orders with greater than 1000 feet of track. Call for information. (Cost is an additional $3.00 per foot).

Talk to an ergo expert: (888) 420-3200 or Email Us

RT

SLIDING MOUNTS FOR TVs, MONITORS AND OTHER EQUIPMENT

- Use the Roller Track to slide TVs, monitors and various equipment with finger-tip ease

- Order an overhead sliding TV mount configured to fit your mounting location by contacting our team

- Multiple Mount Kit options compatible with all SERIES-118 monitor arms and other mounting devices

- Trolley mount (MKIT-N2) moves monitor and equipment up to 100 lb along the track

- Heavy duty trolleys and poles are available for TVs up to 85 inches

- Fixed mounting options are available when instant lateral motion is not required

- MKIT-M2 is a “lift and slide” movable mount with a simple lever brake to lock it in place

- Add one or more of Ergomart’s monitor arms for vertical reach and mobility

- Use with horizontal extensions and pole mounted assemblies for added versatility

- High capacity cable management trough handles cables and even surge suppressors

- Power/video/data cables are routed using a drag chain running inside the wire management channel

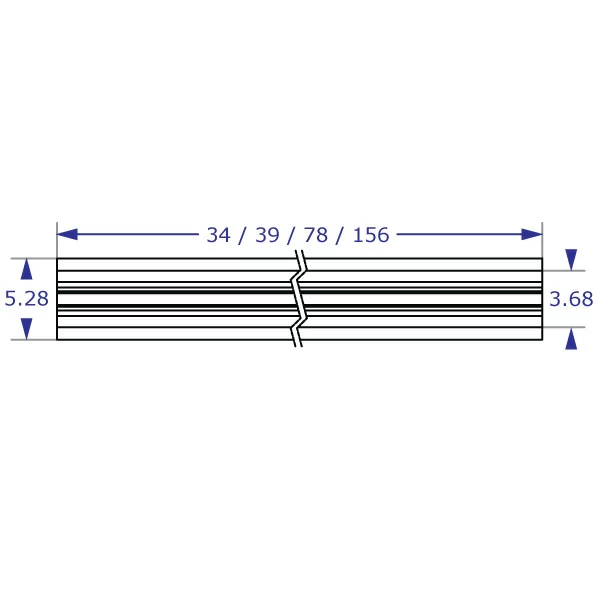

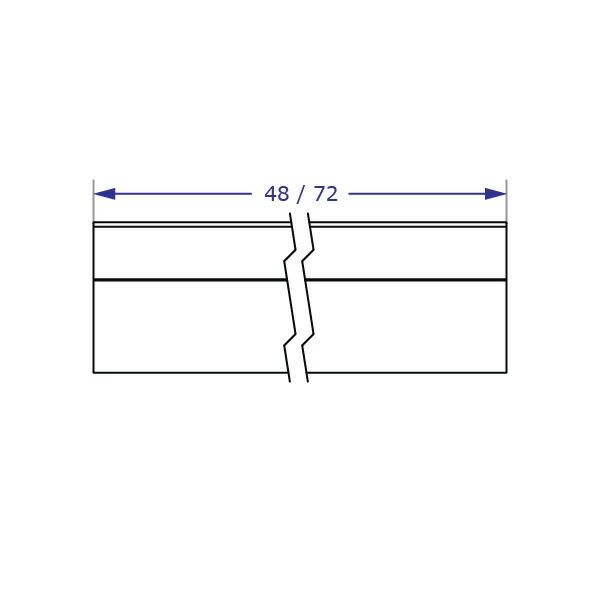

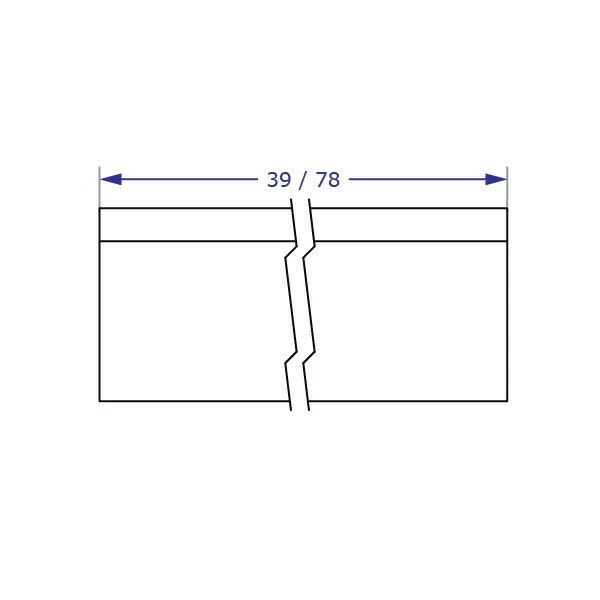

- Standard tracks are available in 34, 39, 78 and 156 inch lengths

- Professional Installation required - must attach to wood studs or correctly engineered heavy backer

- Need a lighter duty alternative? See the New ViewTrack

The Ergomart Roller Track (R-Track) System is a heavy-duty horizontal track/rail that allows equipment to slide or roll laterally with ease. The R-Track System provides a unique and powerful set of answers to meet many mounting challenges encountered across a broad range of applications and environments. This specialty mounting solution is ideal for technical, manufacturing and industrial workstations, broadcast and monitoring environments and medical facilities where sliding monitor mounts are needed. A variety of Ergomart lifting arms and mounts work in conjunction with mobile trolleys or repositionable brackets to deliver vertical travel of up to 28".

Unlike most slat-wall systems, the R-Track can manage substantial loads between 24" fastening locations. The Rail component can handle 90 pound loads with four feet of space between anchoring points while still providing instant lateral mobility. The R-Track system is ideally suited for pairing with dynamic work environments like ball transfer tables and conveyor based manufacturing environments where a monitor and other equipment can be continuously repositioned for optimal usability.

The R-Track system serves as a scalable wall mounting infrastructure accommodating countless possibilities for reconfiguration and expansion while maintaining organization and visual harmony as equipment needs evolve. Dynamically height-adjustable systems result by mounting compatible monitor, keyboard, or other equipment arms to the available RT Mount Kits. These products can be ordered from their respective product pages or you may contact Ergomart for a configuration quoted to your exact requirements.

When fixed height positioning is needed, a combination of Straight Arms, Poles, Pole Mounts, Monitor Tilter Heads and VESA adapters can be used to achieve the desired result. A simple system consists of monitors mounted close to the track using a short horizontal arm, and the appropriate tilter head and VESA plate combination. A longer horizontal arm can provide additional separation from the wall. A pole attached to the RT Mount or to the receiver at the end of the arm can provide vertical reach. Pole mounts allow equipment to be positioned along the shaft of the pole and come in single or dual mount varieties.

The R-Track is for:

- Equipment moved frequently (e.g., audio visual studios, manufacturing or packing workstations)

- Monitors or other devices mounted overhead and moved laterally and pulled down for user interface and then pushed back out of the way after use (e.g., medical/patient care)

- Equipment that must be added or replaced relatively frequently (e.g., showrooms, stores, gyms, restaurants and sports bars, growing businesses)

- Disparate sized monitors that need to be arranged on a wall in logical and useful configurations to create order and organization (e.g., security monitoring stations, showrooms)

For assistance putting together a customized R-Track solution call 1-888-420-3200 (international +1 214-742-6066)

RT RAIL

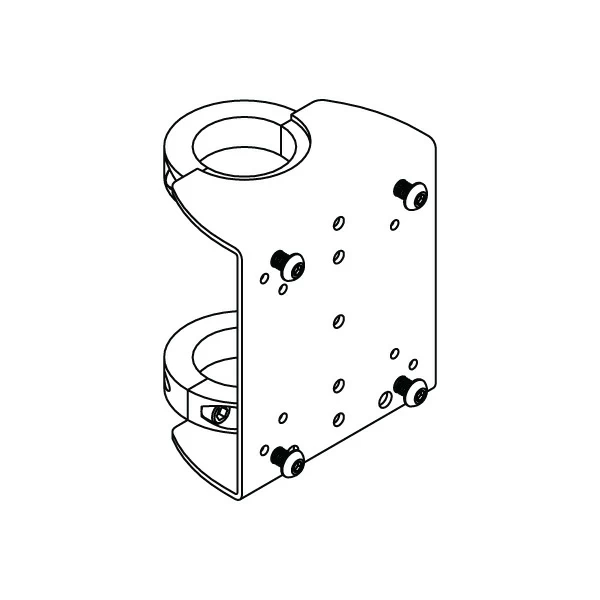

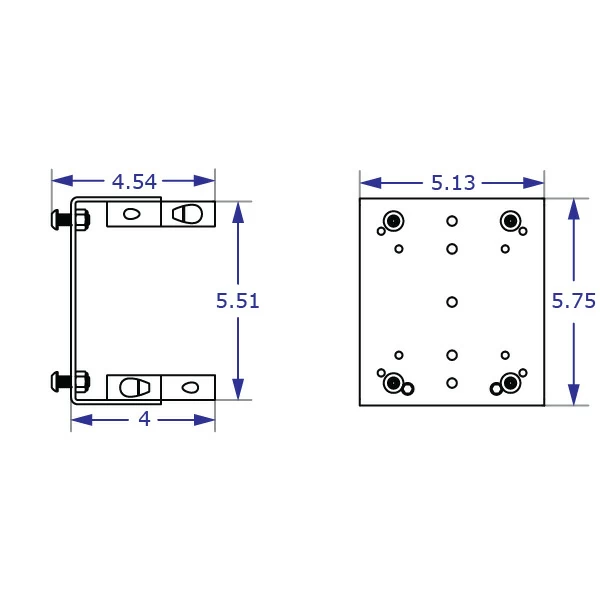

RT CLAMP BLOCKS

RT MOUNT KIT M2

RT MOUNT KIT N2

RT MOUNT KIT N

192 D BRACKET CLAMPS

RT WIRE MANAGEMENT TROUGH

RT CLAMP EXTRUSIONS

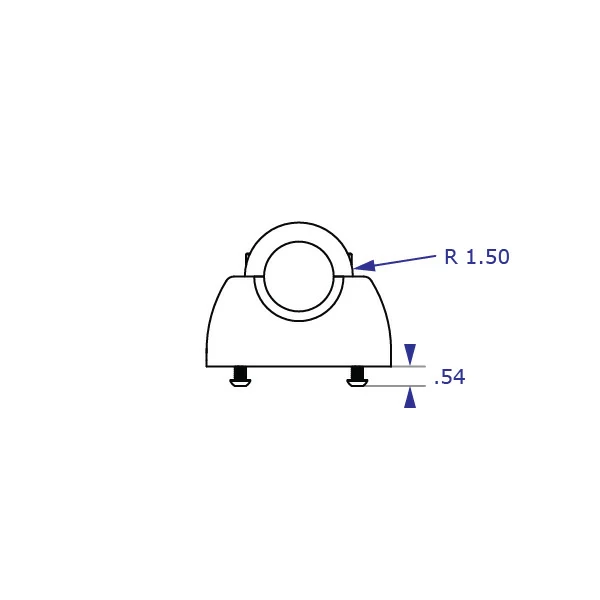

R-TRACK SHAFT COLLAR

Straight Arms, Poles, Pole Mounts, Tilter Heads and VESA adaptors can be used to create customized fixed-height mounting solutions that complement our sizable offering of off-the-shelf solutions. All types and sizes of monitors can be mounted tight to the track or using horizontal arms of differing lengths. Various monitor tilter heads can accommodate monitors weighing up to 75 lb. Pole mounts allow equipment to be positioned along the shaft of the pole above and/or below the mount and come in single or dual mount varieties. Please call for help in creating a solution that suits your specific needs.

| Shipping Weight | Varies depending on order. Call for non-UPS ground shipping arrangements. |

| Shipping Dimensions | Varies depending on order. Call for non-UPS ground shipping arrangements. |

| Warranty | 5 year limited |

| RT Rail is aluminum manufactured with 70% - 100% post industrial and post consumer content and is fully recyclable. | |

| Optional Wire Management Trough is fully recyclable. | |

|

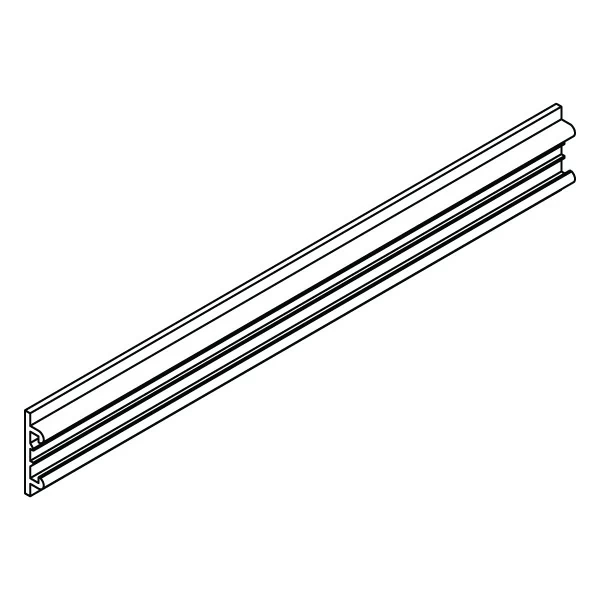

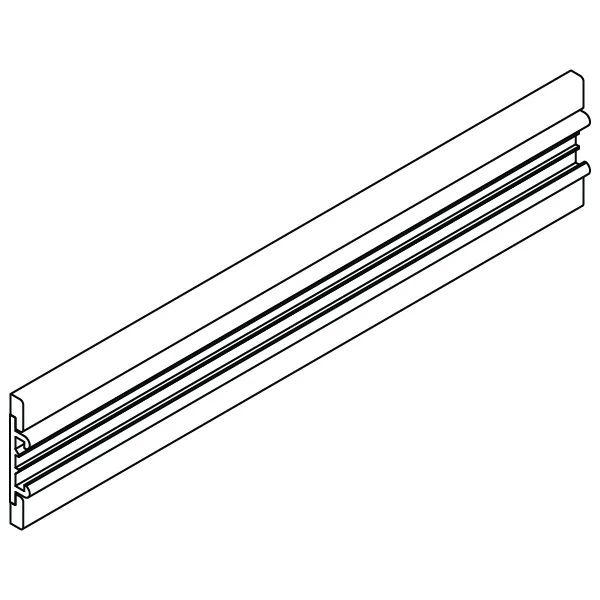

ROLLER TRACK

TRACK - ISOMETRIC VIEW

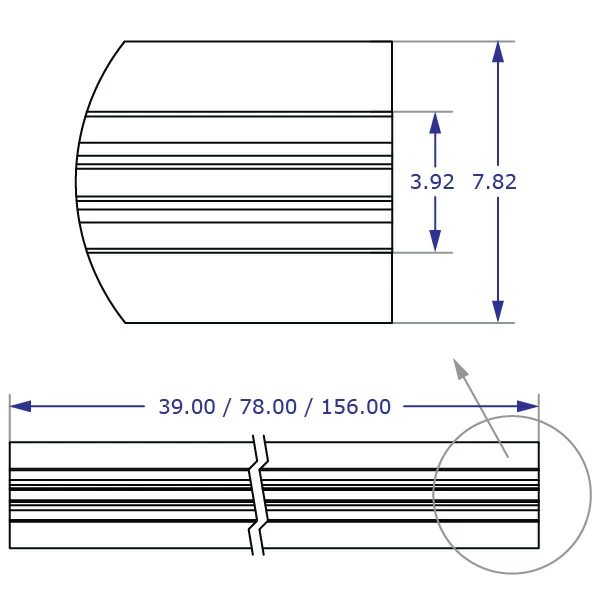

ROLLER TRACK

TRACK - FRONT VIEW

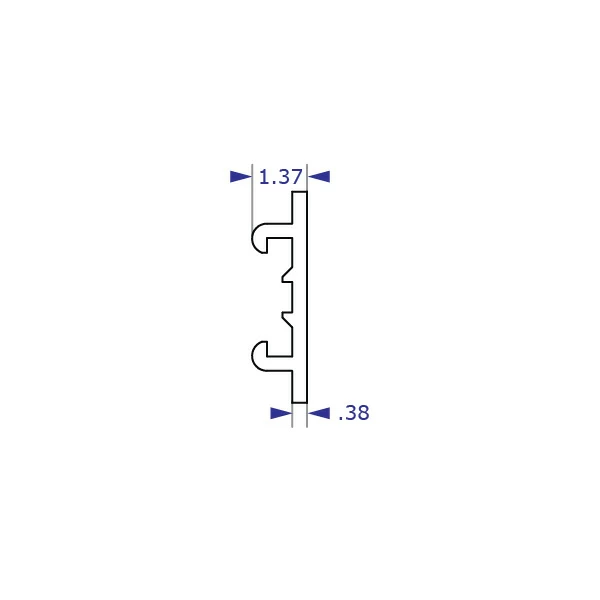

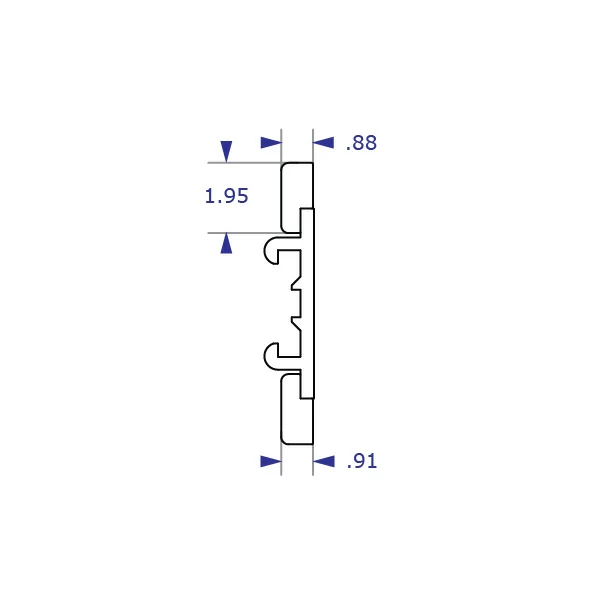

ROLLER TRACK

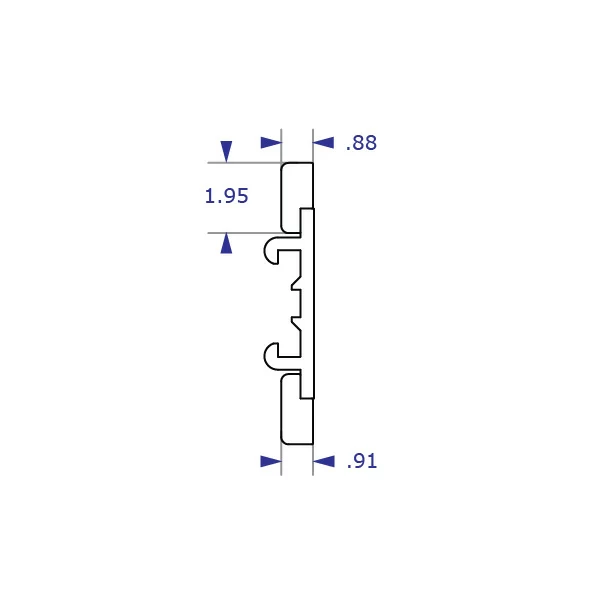

TRACK - SIDE VIEW

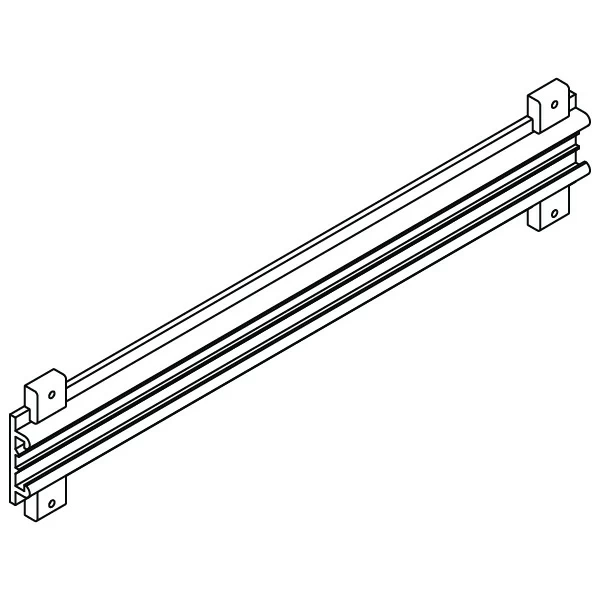

ROLLER TRACK

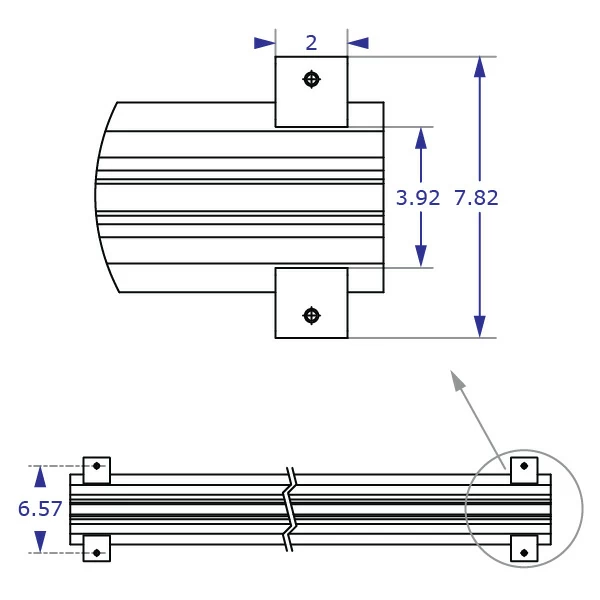

WITH CLAMP BLOCKS - ISOMETRIC VIEW

ROLLER TRACK

CLAMP BLOCKS - FRONT VIEW

ROLLER TRACK

CLAMP BLOCKS - SIDE VIEW

ROLLER TRACK

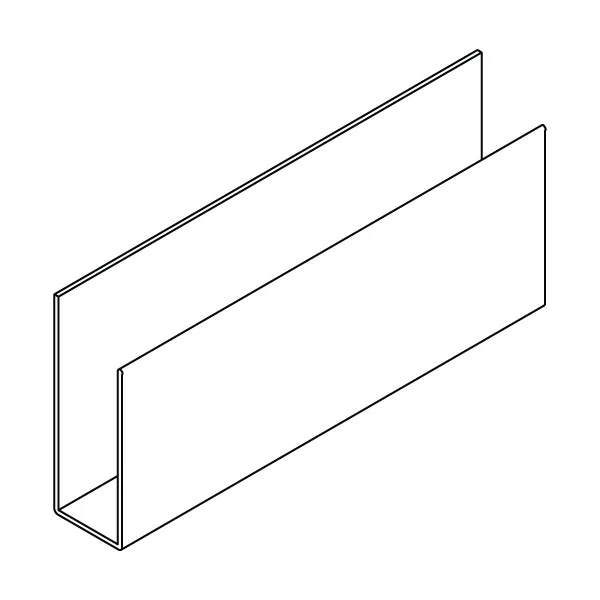

WITH CLAMP EXTRUSIONS - ISOMETRIC VIEW

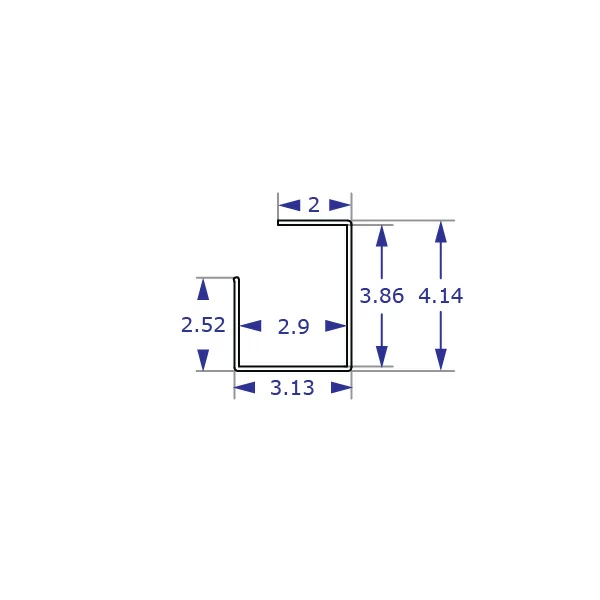

ROLLER TRACK

CLAMP EXTRUSIONS - FRONT VIEW

ROLLER TRACK

CLAMP EXTRUSIONS - SIDE VIEW

ROLLER TRACK

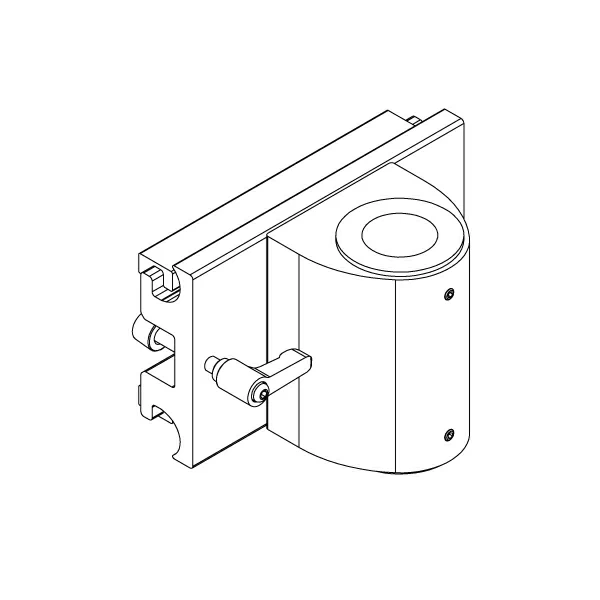

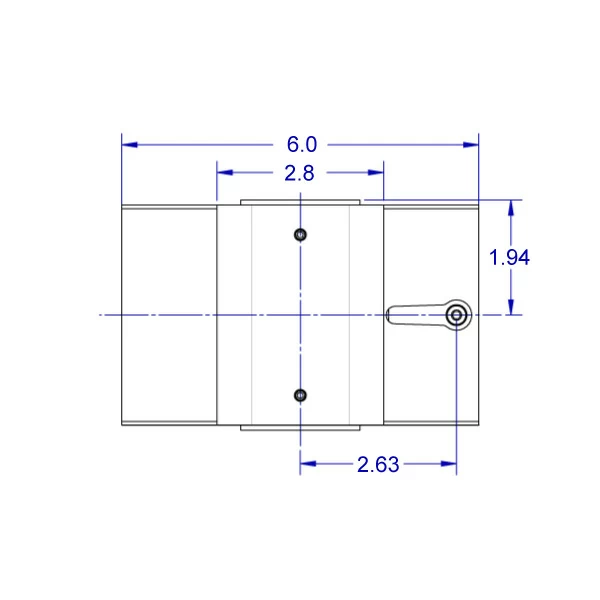

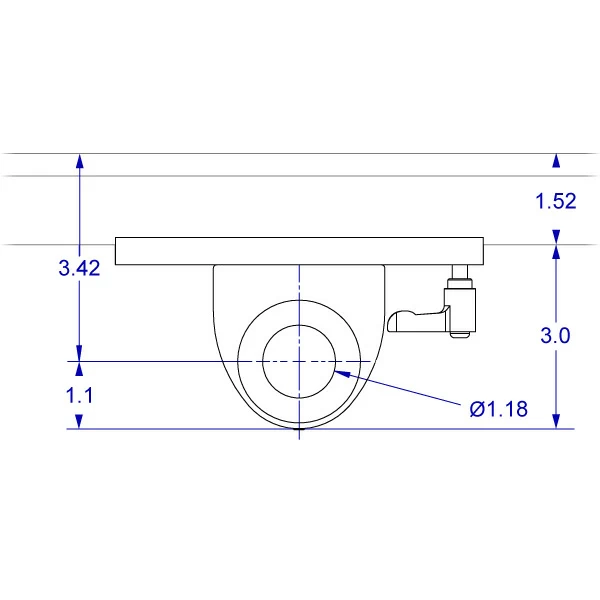

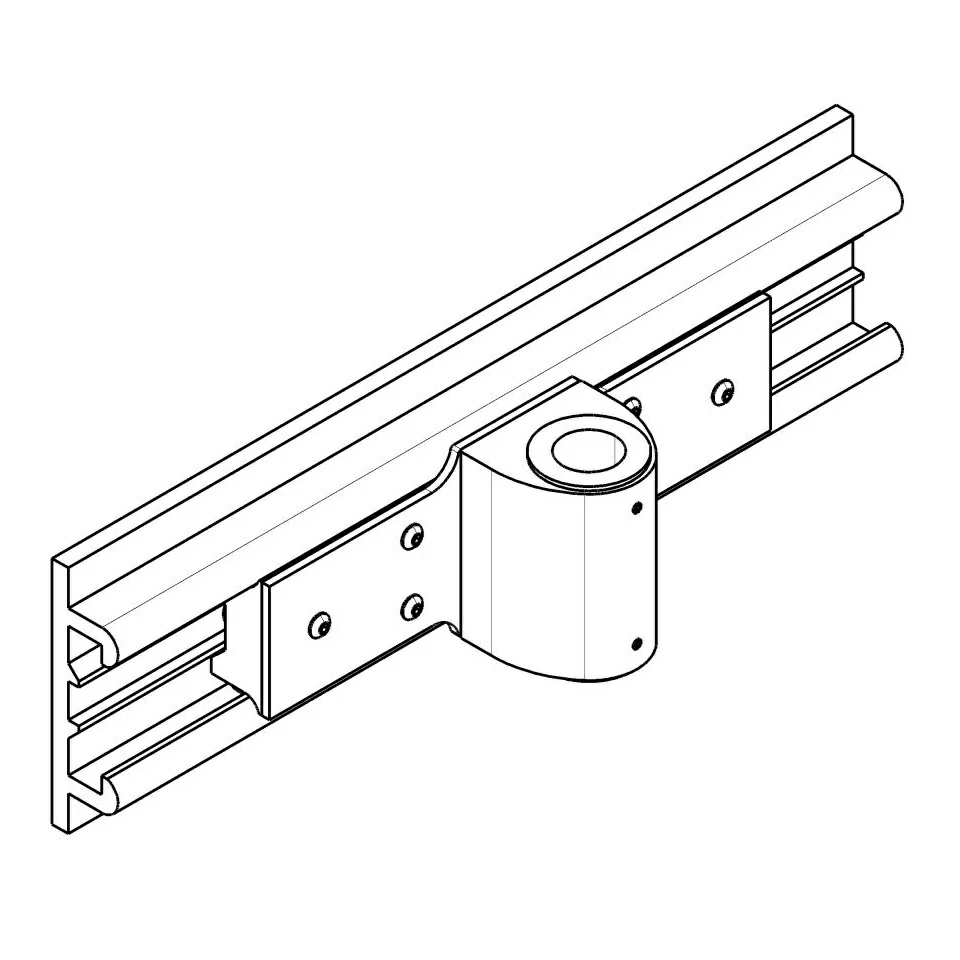

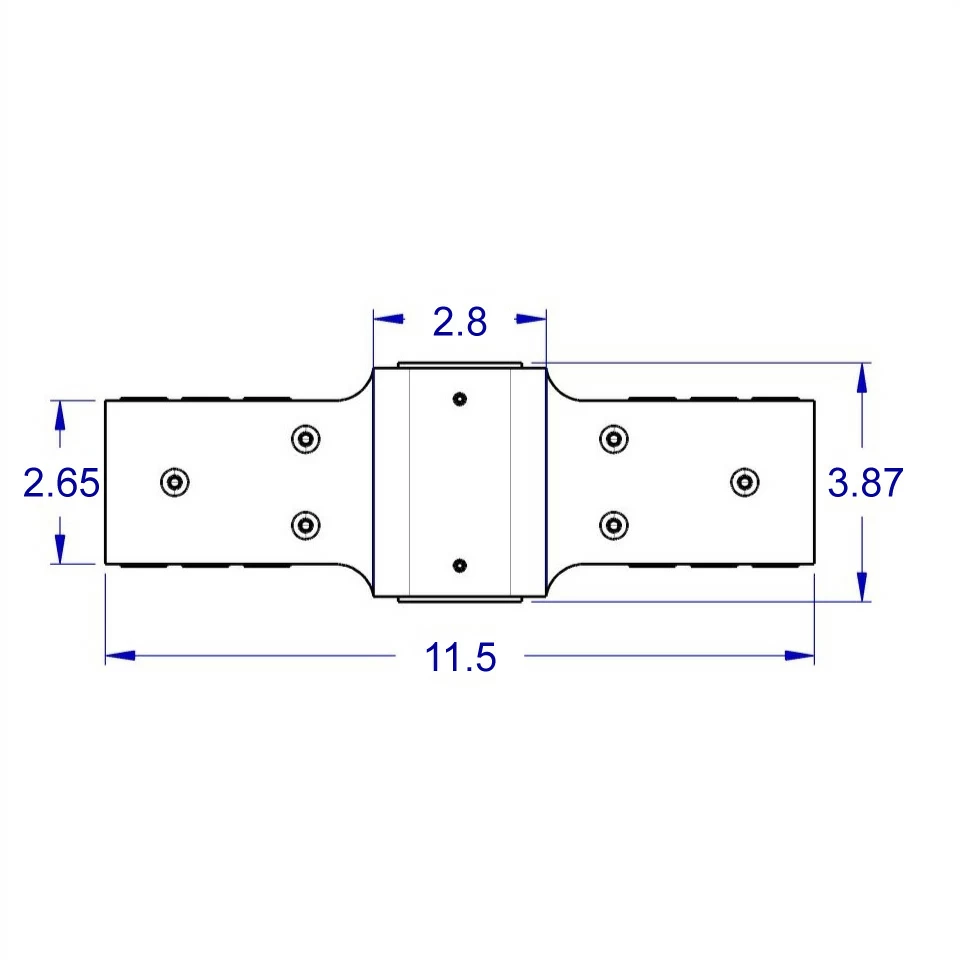

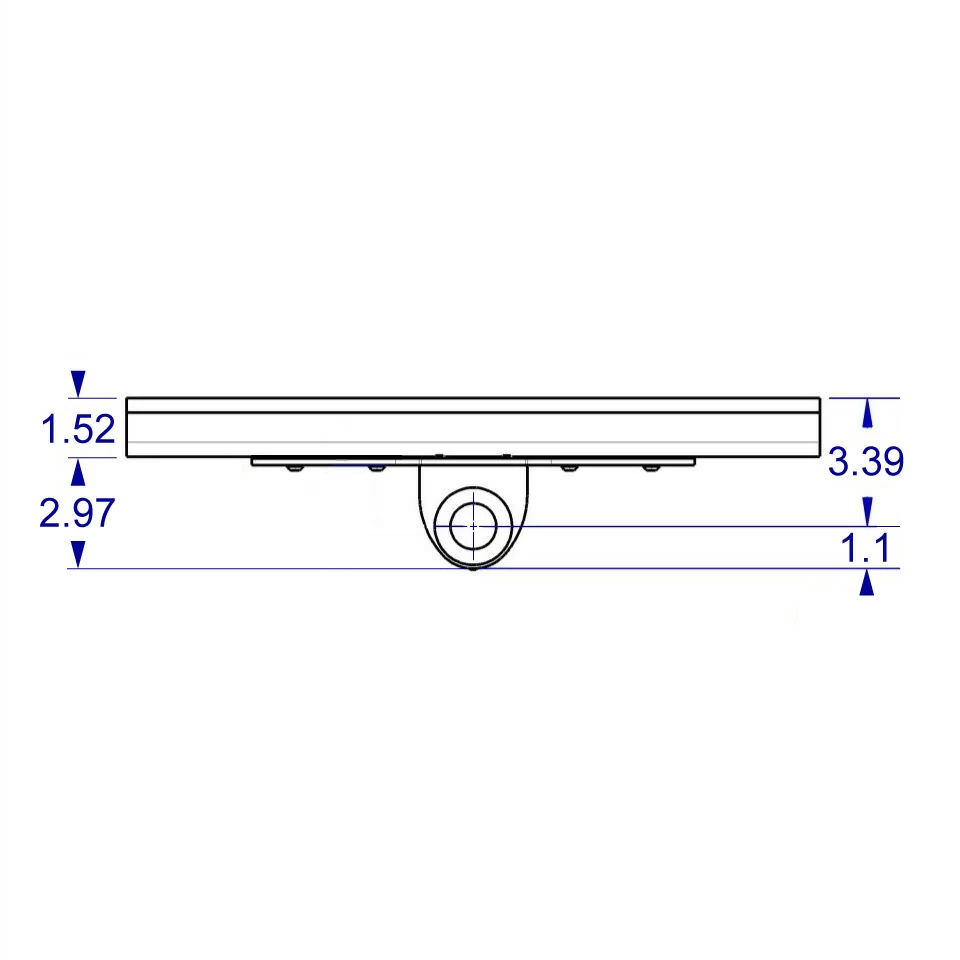

MOUNT KIT M2 - ISOMETRIC VIEW

ROLLER TRACK

MOUNT KIT M2 - FRONT VIEW

ROLLER TRACK

MOUNT KIT M2 - TOP VIEW

ROLLER TRACK

MOUNT KIT N2 - ISOMETRIC VIEW

ROLLER TRACK

MOUNT KIT N2 - FRONT VIEW

ROLLER TRACK

MOUNT KIT N2 - TOP VIEW

ROLLER TRACK

192D BRACKET CLAMP - ISOMETRIC VIEW

ROLLER TRACK

192D BRACKET CLAMP - FRONT & SIDE VIEW

ROLLER TRACK

192D BRACKET CLAMP - TOP VIEW

ROLLER TRACK

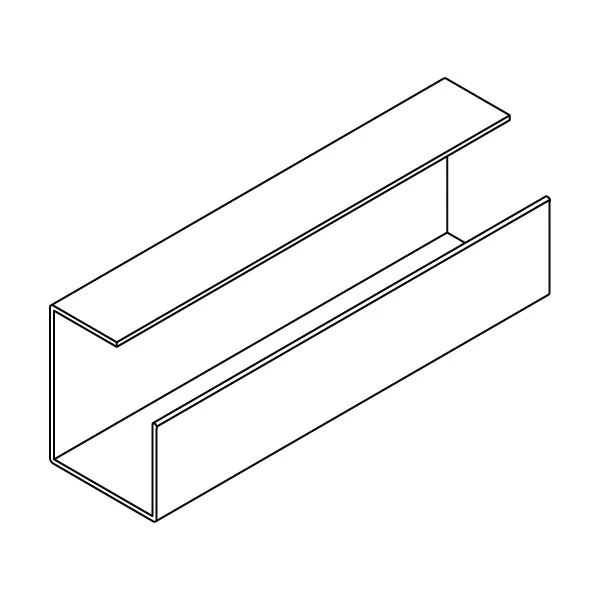

C CHANNEL - ISOMETRIC VIEW

ROLLER TRACK

C CHANNEL - FRONT VIEW

ROLLER TRACK

C CHANNEL - SIDE VIEW

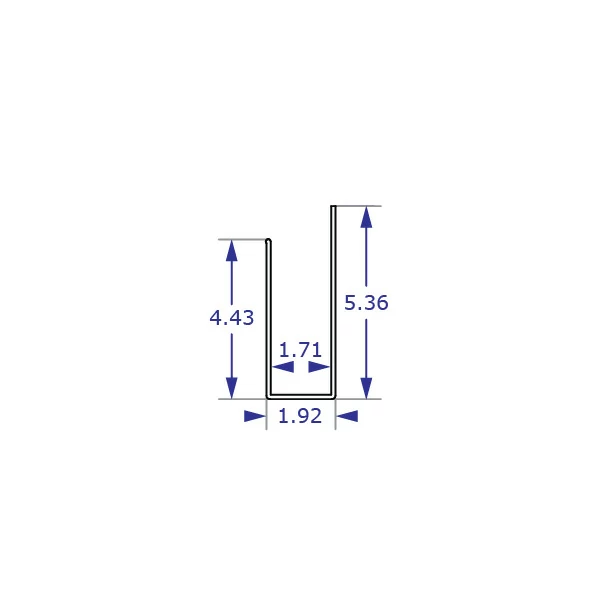

ROLLER TRACK

J CHANNEL - ISOMETRIC VIEW

ROLLER TRACK

J CHANNEL - FRONT VIEW

ROLLER TRACK

J CHANNEL - SIDE VIEW

-

Why does the rail/track come in a silver color and not black like many of the other components?

-

Can I attach this to a sheetrock wall with steel studs without further reinforcement?

The short answer is no. In some cases when the device or devices are very light and are flush mounted to the rail and not subject to movement, sheet rock mounting may be permissible. Since the system is designed for movement and the repositioning of components, intermittent and abrupt mechanical stresses are transmitted to the fasteners. The fasteners slowly pulverize the gypsum media every time a vibration is transmitted through them. Sheet rock alone is not suitable when presented with repeated changes in mechanical pressure. Consult a mechanical engineer and/or use a competent equipment installation professional to determine the type of reinforcement requirements for your installation.

-

Can I attach this to a sheetrock wall with wood studs without further reinforcement?

In most cases, serviceable wood studs on 16 or 24 inch centers make the perfect mounting medium. It’s never a bad idea to consult a mechanical engineer and/or use an equipment installation professional to determine the reinforcement requirements for your installation.

-

Why would I need the RT Clamp blocks?

RT Clamp blocks are typically used as a means of attachment on certain exposed vertical standards (unistrut) and tracks on technical and manufacturing desks and tables. They may be attached so that they accept the rail from the bottom during installation. Top clamp blocks are then clamped along the top RT flange to secure the rail to the structure. They can also be used to enhance security by providing an additional point of attachment to prevent the track from pulling away from the structure to which it is attached. Normally, ff you fasten through the flanges, the clips will not be necessary.

-

Why don’t you include fasteners for attaching to the wall?

Ergomart can warrant the mechanical capacities and limits of the products it designs and sells but can’t know the properties and reliability of the media to which our products will be attached. Methods of attachment to various surfaces and structures can only be deemed appropriate by trained personnel on site. Consult with a mechanical engineer or work with an equipment installation professional to determine the correct fastening system in the actual application.

-

Is Roller Track made in the USA?

Yes, the roller track system and the mounting components that receive and support arms and pole components are manufactured in the USA. Ergomart strives to manufacture and source as much product from the USA as is competitively possible.

-

What is UNISTRUT or Strut Channel and how does that work?

Information on Unistrut or Strut Channel can be found here: http://en.wikipedia.org/wiki/Strut_channel

Besides being used widely in the construction industry for supporting lightweight loads of ceilings, it is used by many OEM workbench manufacturers. The front open side allows for the attachment of various bench components and accessories as well as add-ons such as the R-Track. -

Can I attach CPUs or other devices on the track behind my monitors?

Yes – determine your requirements and contact us. Options that include a thin client holder are readily available. We are happy to work with our customers to build affordable custom solutions for short production runs. Virtually any accessory requirement you desire can be accommodated.

-

Will I have to drill holes in the track to attach the track to my wall (or unistrut)?

Yes, custom installation is the norm for this product and it is not designed as a "slap-it-together-in-ten-minute-DIY-project". The installer should be familiar with attaching heavy loads to varying materials and locations. In special circumstances, Ergomart can custom-drill RT Rails however lead times will be extended.

-

I think slatwall will do the job for me, why should I consider the more expensive R-Track?

In many applications, slatwall is the appropriate solution. But, sometimes the RT track can be competitive with costs or the performance associated with slatwall. There are many applications where the R-Track may prove a better fit:

• Where strength is a concern and the need to span unsupported widths are required

• Above or behind workstations with individual struts or poles as anchoring points

• Where aesthetics are important and a slatwall does not communicate a look of robustness or strength

• Attached to a freestanding frame where “walk behind" access to cabling and wiring is important -

I think the R-track is overkill to mount FOUR (27”) 14 pound monitors and move them occasionally. They only need to tilt down a little bit. I really think the R-track is overkill. How can we bring the price down?

The new ViewTrack is probably what you need… it is easy to install and will match your requirements for less than $400. And if you are OK with simply flush mounting your monitors then you are only looking at about $200!