Talk to an ergo expert: (888) 420-3200 or Email Us

SERIES-118 MODULAR MOUNTING

The SERIES-118 modular mounting system consists of a large catalog of products designed with compatibility, customization, scalability and cost-efficiency in mind.Flexibility. The number of interchangeable components offered with SERIES-118 provide the ability to create systems that solve a variety of problems with the same large set of tools.

Configurability. The modularity of the system enables to design of solutions not only for common uses as well as non-standard requirements. For example, the SERIES-118 system is suitable for organizing disparate-sized monitors or equipment requiring various levels of adjustability. A large project may consist of mostly similar mounts but certain workspace or end-user constraints often require the solution to be tailored on a case-by-case basis. The options available within the SERIES-118 modular mounting system allow it to easily handle such exceptions.

Future-Proofing. Many of the components of the modular system are interchangeable and easily replaceable. This allows users to scale up, down, or make replacements when needs or mounted peripherals change without the cost burden of an entirely new system.

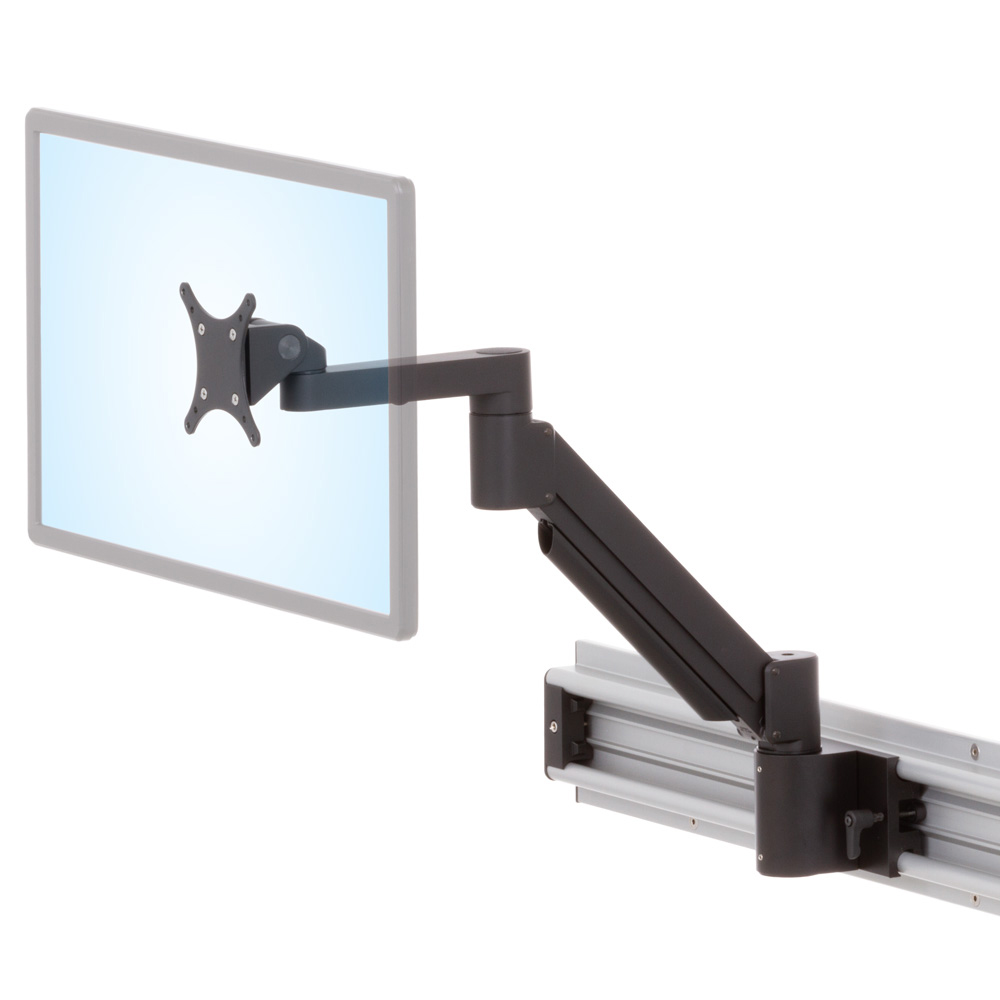

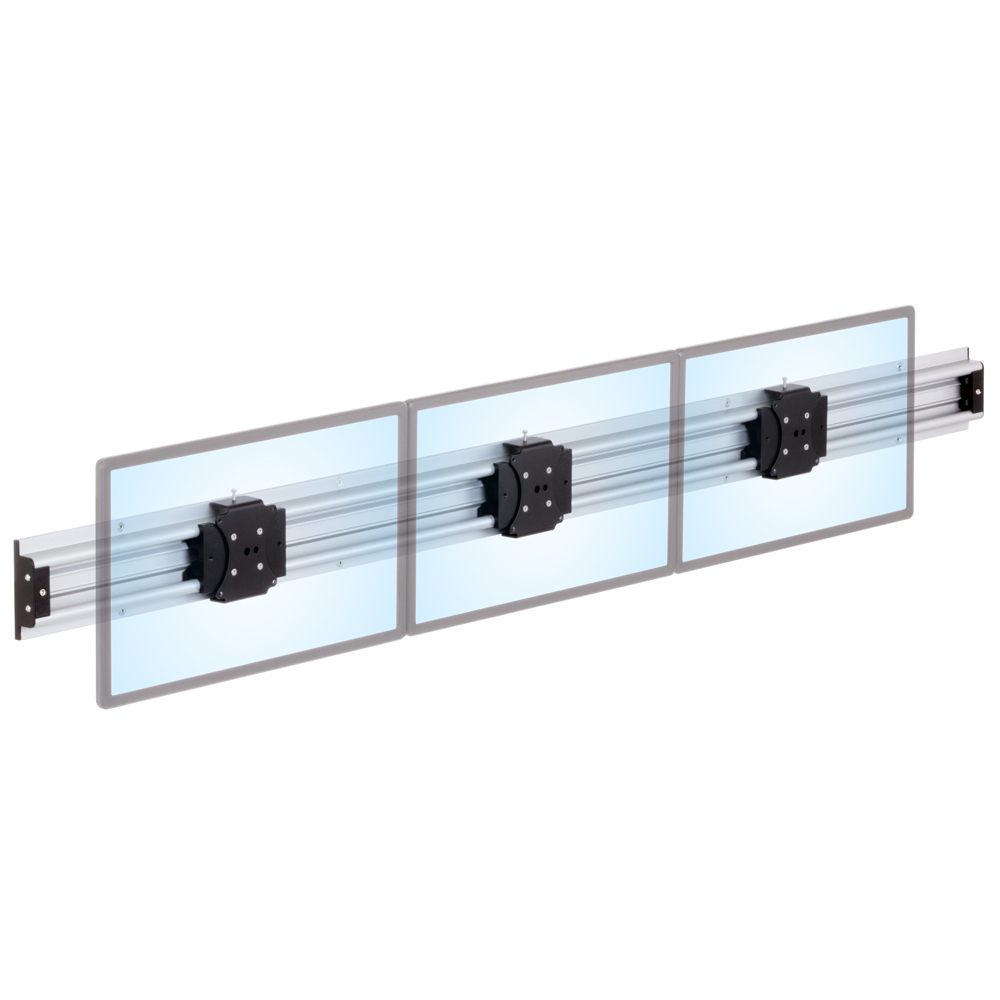

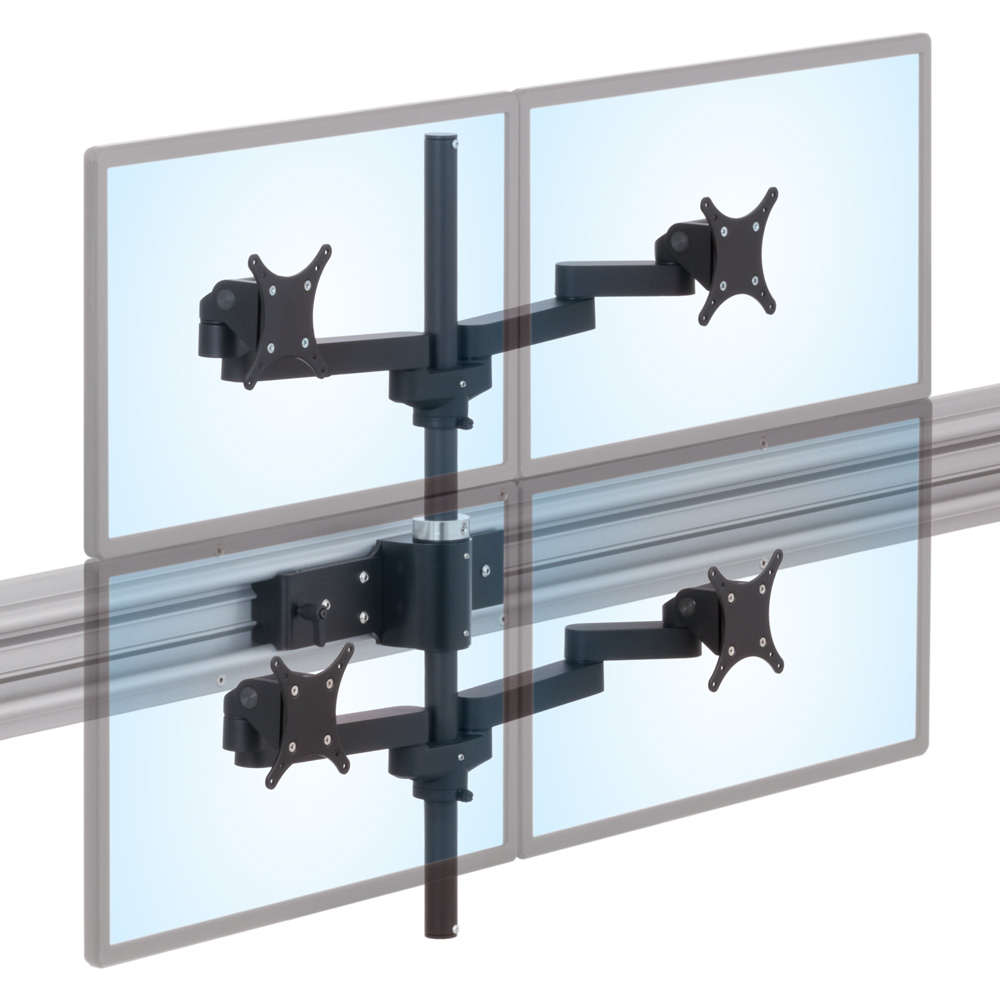

There are three key components to a SERIES-118 modular system: the optional mounting platform (e.g. a pole or a track), the mounting kit (e.g. a receiver for the mounting device) and mounting device (e.g. an arm, stand or other mounting equipment). Multiple mounting kits and mounting devices can be used with a single mounting platform. Certain mounting kits can also be used without the mounting platform and instead directly mount to various surfaces, such as desks, walls or medical equipment, depending on the Mounting Kit used. The full range of available Mounting Kits can be viewed on the Mounting Kits page.

SERIES-118 includes four mounting platforms: P192 pole mounts, MCART rolling carts, EC TRACK vertical wall track and the ROLLER TRACK horizontal track mount. For detailed information on the Roller Track mounting platform, see the Roller Track Rail tab of this guide.

Mounting Kits are used to interface the mounting platform with the mounting device to which a monitor, keyboard or other peripheral can be attached. For the wall-mounted Roller Track, the SERIES-118 mounting kits are MKIT-M2, MKIT-N2 and the first generation MKIT-M and MKIT-N. They provide different levels of horizontal movement along the track as well as different weight range capacities. While the mounting kits have a specified weight range, the actual supported payloads of the device depend on many factors such as fastener location and distance of the peripheral from the track.

MKIT-N2 Trolley Mounting Kit

Mount Kit N2 is an 11.5”-wide trolley with 18 sturdy roller bearings. It is capable of moving up to 100 pounds quietly along the length of the RT rail with virtually no resistance for many years of trouble-free use. It comes with an optional brake component so the mount can be immobilized at the desired location with the turn of the ratcheting brake knob to prevent unintended movement.

Mount Kit N2 is an 11.5”-wide trolley with 18 sturdy roller bearings. It is capable of moving up to 100 pounds quietly along the length of the RT rail with virtually no resistance for many years of trouble-free use. It comes with an optional brake component so the mount can be immobilized at the desired location with the turn of the ratcheting brake knob to prevent unintended movement.

MKIT-M2 Positioner Mounting Kit

Mount Kit M2 is 6” wide and can accommodate up to 8 monitors. This mount is a sturdy, fixed interface and can support up to 150 pounds. Its brake knob can be loosened to easily “lift and shift” lighter payloads laterally. Two friction resistance set-screws within the mounting column press against durable acetal bushings that in turn lock poles and arms into a fixed position to prevent left/right swivel when desired.

Mount Kit M2 is 6” wide and can accommodate up to 8 monitors. This mount is a sturdy, fixed interface and can support up to 150 pounds. Its brake knob can be loosened to easily “lift and shift” lighter payloads laterally. Two friction resistance set-screws within the mounting column press against durable acetal bushings that in turn lock poles and arms into a fixed position to prevent left/right swivel when desired.

First Generation MKIT-N Trolley Mounting Kit

Mount Kit N is a 12" wide heavy-duty mount with a roller track trolley. It is designed to move freely along the length of the rail so that equipment mounted on the R-Track is repositioned effortlessly. These kits can be retro-fitted with an optional brake if desired.

Mount Kit N is a 12" wide heavy-duty mount with a roller track trolley. It is designed to move freely along the length of the rail so that equipment mounted on the R-Track is repositioned effortlessly. These kits can be retro-fitted with an optional brake if desired.

First Generation MKIT-M Positioner Mounting Kit

Mount Kit M is 6" wide and fixed. It is designed to be secured to the RT rail with four set screws for stationary positioning of equipment. This is best for occasional reconfiguration of the mounted equipment.

Mount Kit M is 6" wide and fixed. It is designed to be secured to the RT rail with four set screws for stationary positioning of equipment. This is best for occasional reconfiguration of the mounted equipment.

The MKIT-Q desktop trolley and MKIT-V desktop positioner are utilized when the Roller Track is attached along a horizontal surface while the MKIT-U ceiling troller and MKIT-W ceiling positioner are used for Roller Track ceiling mounting.

Fitted into the mounting kits are VESA-compatible mounting devices for monitors, TVs, tablets, keyboards and other peripherals, each with varying height and depth adjustment, tilt, swivel and rotation capabilities. Ergomart’s SERIES-118 modular mount selection is large and incredibly customizable. Not only can many fixed-height and height adjustable arms and workstations be fitted into the SERIES-118 mount kits - poles can also be attached, allowing for multiple monitors to be mounted both above and below the track on a single mounting kit.

Fixed-Height Mounting

Height-Adjustable Mounting

Multi-Monitor Track Mounting

Multi-Monitor Mount Kit Mounting

Ergomart has pre-assembled several Complete Kits composed of SERIES-118 components which can be reviewed on the Complete Kits tab of this reference guide. These kits provide a convenient way to create solutions for the more commonly encountered Roller Track applications.

SERIES-118 components also includes a range of accessories that can also be added to the Roller track to facilitate monitor adjustment, increase monitor reach or provide additional positioning capability for devices such as CPUs or barcode scanners.

Ergomart representatives are always on hand to help you configure a Roller Track system suited to your specific application. Please don’t hesitate to contact us at 888 420 3200 or [email protected] with any questions.