Talk to an ergo expert: (888) 420-3200 or Email Us

Roller Track Weight Ratings and Installation Notes

The RT1 Roller Track system is designed to handle heavy loads when installed and operated correctly. The weight capacity and mechanical limitations of any Roller Track installation are determined by the weakest component. Ergomart can assist you during each step of the analysis and decision making process or simply support you with final weight ratings and capacity information.

Three Step Process for Selecting Simple Flush Mount Options

A - Select the mount and VESA bracket appropriate for your payload

B - Review table below for minimum fastener spacing requirements (see Appendix A)

C - Ensure structural viability for your application > your responsibility <

- Your onsite installation professional or engineer will ensure that your structure is suitable for the loads inherent with the system you have specified as well as determining that the recommended fasteners are appropriate for the mounting structure.

Four Step Process for Building Modular Solutions with M2 and N2 Mounts

A - Configure a system using one of three approaches

- Select and configure one of the four RT-EZ baseline offerings pre-kitted to satisfy many common requirements or

- Work independently or with our assistance to assemble a system based on our many available modular components or

- Engage with Ergomart’s technical sales team to build a solution with customized components that meet your goals

B - Document requirements, conditions and payloads (see Appendix B)

- Provide Ergomart with your payload and equipment package requirement

- Provide all part numbers and their positions relative to each other:

- Fastener centers intervals

- Mounts, Extensions and Arms

- Document minimum Carriage Intervals (closest distances between positioners or trolleys)

C - Components analysis, report and recommendations

- Determine suitability and compatibility of components, equipment and final payloads

- Ergomart engineering will verify your maximum viable fastener spacing with respect to rail capacities

- Ergomart will advise where changes are required and possible options if a component is overloaded

D - Ensure structural viability for intended application > your responsibility <

- Your onsite installation professional or engineer will ensure that your structure is suitable for the loads inherent with the system you have specified as well as determining that the recommended fasteners are appropriate.

Installer Responsibilities and Installation Considerations

The maximum load allowed by the Roller Track rail and the fasteners used to attach it to a mounting surface depends on multiple factors.

Wall and surface characteristics The load bearing wall or vertical interface that supports the Roller Track must be flat or shimmed flat and immobile with respect to the intended load and include physical properties that ensure that the fasteners do not pull through the mounting medium at the attachment points. The functionally immovable object (wall) and its surface structure will have a combined structural integrity acting as a unitary object. A typical office partition wall is not suitable for supporting roller tracks in most applications. Some type of substructure must be added in thin gage steel stud installations and this is why a professional installer or engineer is required.

Materials used in building construction vary extensively. Typically the fastener strength is the focal point in surface mounted assemblies but the attachment or base material itself can be the actual weak link within an overall design. The base material is a critical factor in the selection of an anchor or fastener because it must be able to sustain the applied loads. Base material strengths vary widely from substrate to substrate and therefore become the key factor in the performance of an anchor or fastener. Generally, appropriate fasteners that are installed in denser concrete and stone can withstand far greater stress than fasteners installed in softer materials such as lightweight concrete, CMU block, brick, or wood.

IMPORTANT NOTE: Shims and/or sheetrock will increase bending stress experienced on fasteners. Consult an engineer or professional installer to ensure that your structure and any overlaid materials will provide attachment-point support for the fasteners.

As in all applications, the load capacity and other criteria used to determine a fastening system's suitability should be reviewed and verified by a professional responsible for the actual product installation.

Dynamic stresses A structural engineer or professional installer must determine a mounting structure's appropriateness where equipment use and related activities will create dynamic loading stresses including vibration and impact loading. Dynamic stress factors are outside the scope of our testing and analysis and therefore become the responsibility of the onsite project engineer or installer.

Rail mounting holes The Roller Track Rail is mounted to a vertical surface using fasteners in a series of clearance hole pairs in the upper and lower flanges. Typically, the installer is responsible for drilling these holes. ¼-20 fastener specifications are noted below. Smaller screws are not permissible and have not been tested and should therefore never be used. The maximum clearance hole diameter will be .266” when using ¼” machine screws. When using 5/16” machine screws or bolts a maximum hole diameter of .332” is permissible. Depending on the installation, the spacing between fastening point centers are dictated by the required total payload of the RT1 roller track.

Two types of tested and recommended fasteners for many typical applications Ergomart specifies two types of fasteners depending on the mounting surface and its underlying structure. Ensure your mounting structure is capable of handling the maximum loading specified for these fasteners.

- ASTM F835 ¼-20 Machine Screws

- GRK RSS ¼ Structural Screws - specification

Note that the above countersunk ¼-20 machine screw and GRK RSS screw will provide operational clearance and compatibility with all Ergomart Roller Track equipment and accessories.

ASTM F835 ¼-20 machine screws with toggles Our minimum requirement for rail mounting stipulates the use of ¼”-20 hex drive flat head machine screws that meet or exceed the ASTM F835 specification. It should go without saying that fasteners must be properly tightened and never over-torqued which will weaken the fastener. Similar 5/16”- 18 fasteners manufactured to the ASTM F835 standard will exceed the performance for the minimum specified ¼-20” and may be used in their place. These toggles would never be used with a typical steel stud partition wall that does not have professionally installed blocking. Always work with an engineer or professional installer to ensure your wall is structurally capable of handling the intended load.

ASTM F835 ¼-20 machine screws inserted into threaded holes These machine screws may be successfully used in conjunction with adjacent immovable steel or aluminum surfaces allowing more than 8 threads of actual screw thread to hole thread engagement.

Attachment to wood studs using GRK RSS ¼ x 3-1/8 structural screws Wood studs present many variables that make a broad formal analysis impossible based on inconsistencies in the physical properties of the various species, variability within a single species, treatment, age, environmental conditions and storage of the wood. Using industry standard blocking techniques with 2 x 12 Wood Studs can provide a suitable sub-structure capable of supporting the stresses created by a fully loaded Roller Track. It is the responsibility of the installer or engineer to determine if the specific wood substrate will function as expected when the fasteners are fully and properly engaged.

Standard wood screws and lag screws for wood are not recommended Unlike the aforementioned machine screws and structural wood screws, wood screws and lag screws are not manufactured to industry specifications that can be applied to any formal engineering analysis or tested using any sound methodology that would return reliable and repeatable results. Since no consistent data or a general industry specification exists, it is not possible to predict the behavior of these fasteners.

Lag screws for wood attached to wood studs Under the direction and at the discretion of an installation professional lag bolts can be successfully used with important caveats. Lag bolts (3/8ths and 7/16ths) can be specified and then tested on a per project/batch basis under the supervision of a trained professional or structural engineer who is managing the installation. Since lag screws are not manufactured to an industry specification that can be applied to any formal engineering analysis or tested using any sound methodology that would return reliable and repeatable results, Ergomart can not recommend their use for any specific installation. Rely on your onsite professional to determine if lag screws are appropriate.

Potential drawback to using lag screws - interference with some Ergomart components

A substantial drawback to using lag bolts with an RT1 rail installation is that the large hex head will interfere with many RT1 devices and accessories that hug the upper and lower flanges. Check with your Ergomart Sales representative to determine if your intended carriage configurations preclude the use of fasteners with heads that protrude well above the flange surface.

Potential drawback to using lag screws - interference with some Ergomart components

A substantial drawback to using lag bolts with an RT1 rail installation is that the large hex head will interfere with many RT1 devices and accessories that hug the upper and lower flanges. Check with your Ergomart Sales representative to determine if your intended carriage configurations preclude the use of fasteners with heads that protrude well above the flange surface.

Commercial office thin gage steel stud walls are generally not capable of supporting Roller Tracks The Roller Track system is not designed to be installed against sheetrock that is supported solely by thin gage steel studs. Most office spaces inside commercial buildings are constructed from 20 or 25 gage steel studs that are meant to function as temporary partitions and not as load bearing walls. Ergomart is not able to recommend a specific fastener that would be appropriate without introducing some form of Traditional blocking using high quality 2x12 laterally positioned studs is the preferred solution since it can be used with the GRK RSS ¼ fastener. During the planning stages of a new construction and remodeling project, work with your engineer or architect to make sure sufficient backing is specified to strengthen temporary walls.

Functional opposing plate solution for thin gage steel stud walls It is possible in some circumstances to place a substantial plate (e.g. a 2” x 8” x high quality wood board) on the reverse side of a typical office partition wall to create a clamping or “sandwiching” effect that will support substantial loads. Your Ergomart sales person will connect you with a technical solutions specialist should you wish to explore the approach as an option.

Vertical Unistrut and vertical pole mounting For installations where the Roller Track is attached to completely separated coplanar vertical surfaces (Unistrut, metal columns, poles, vertical members, etc.), contact Ergomart for assistance determining load capacities applicable to your unique project. Specifications noted below DO NOT pertain to loads that are not affixed against a continuous flat supporting surface and therefore are not valid for unbacked Roller Tracks suspended between two or more fastening points.

Mounting to masonry, CMU, stone and other similar materials While it is possible to mount on naturally occurring mineral and rock substrates or manmade non-homogenous materials Ergomart does not recommend any specific method. Each mounting location must be evaluated on a case by case basis by a trained professional. The most common approach typically involves installing an oversized rigid mounting plate or backer board directly to the face of an uneven surface using specific anchoring techniques and tools, This intermediate surface creates the flat interface required to properly mount an RT1 Roller Track.

Installation Notes for Wood Studs and 2 x 12 Wood Blocking

Roller Track attached to rigid vertical studs or substantial blocking Ergomart’s customized no cost analysis of your payload(s) and available mounting intervals determines the maximum allowable distance between each fastening point for non-flush mount kits. This distance can vary from 8” to 48” and is based on a mounting interface that is essentially immovable such as vertical wood studs integrated to the building floor and ceiling structure. Work with Ergomart to determine if your 16” or 24” vertical stud wall is sufficient to support your intended payload or payloads and all mounting equipment between the rail and device(s) whenever planning for a modular component installation. Additional blocking may be required for multiple highly-leveraged and/or substantial payloads.

Lateral spacing of mounting holes on Roller Track During the planning process and before the purchase of the RT1, Ergomart assists its users in determining the greatest allowable distance between each hole for all modular solutions (see four step process above and APPENDIX B).

Locate and mark positions on wall for RT1 Track attachment points

- Your hole positions will be in accord with the planned pattern based on parameters set by the four step process for modular installations or the three step process for flush mounts - Shift hole locations as much as 2 inches left or right to avoid underlying obstructions in walls with lateral blocking.

- End fastening points must be between 1.75 and 6 inches from both ends.

- Hold the rail up to the hole location marks on your wall with the assistance of two helpers.

- Mark hole locations along top edge of track.

- Set the RT1 track face down on a non-marring surface like a sheet or cardboard.

Precisely mark mounting holes on back of track

|

|

| A. Using the location marks from the top edge of the track, transcribe lines across the back side. | B. Mark hole center locations exactly 3/8" from the outer edge on top and bottom flanges. |

For attachment to wood stud walls or 2 inch+ thick solid wood block use GRK RSS ¼ x 3-1/8 screws

- GRK screws far outperform equivalent lag screws in strength

- GRK RSS ¼ x 3-1/8 are available at most Home Depot and Lowe's stores and many other hardware stores as well as online

- Since the GRK screws are brass/beige colored you may wish to spray paint the heads prior to installation to better match the aluminum Roller Track

Warning - never attach to steel stud office partition walls without special wood blocking

- Contact Ergomart for assistance when there is any question about the surface you plan to use

Drill holes in track

- Set the hole locations with a nail set or punch to avoid drill bit walk.

- Drill 1/8” pilot clearance holes from the back while maintaining a perpendicular path through the flange (using a drill guide will help ensure perpendicularity and is recommended).

- Turn the rail over and enlarge each 1/8” pilot clearance hole using a 17/64” drill bit.

- Remove burrs from front and back side of mounting holes using a deburring tool or countersink.

Install rail using GRK RSS ¼ x 3-1/8 screws

- Hold the rail to the desired location on the wall with assistants at both ends of the rail. Carefully level the rail.

- Attach at both ends first using specified GRK screws.

- Affix all fasteners and tighten. Do not over tighten.

Appendix A: Payload Maximums for Flush Mount Kits

The weight capacity of the individual Roller Track mounts typically depends on the type of mount and the distance of the payload from the carriage surface. Wider rail attachment fastening points will reduce the payload maximums of both styles of carriages (Positioners and Trolleys).

Preconfigured flush mounts

The family of Flush Mounts naturally position payloads close to the wall. Both Trolley and Positioner Flush mount ratings are based on payloads with a depth of 4 inches or less when measured from the mounting face.. For payloads with a depth greater than 4 inches, contact Ergomart for assistance in determining payload capacity. The weight and forward projection of all components including any accessories and VESA adaptors must be included in your weight capacity calculation.

Weight capacity for Flush Mounts with part numbers listed below are based on hole intervals and mount type*

| Mount Kits | Type | Maximum Fastener Intervals | |||

| 8 Inch Max | 12 Inch Max | 16 Inch Max | 24 Inch Max | ||

| RTFP-V11, RTFP-V12 | Flush Positioner | 125 | 125 | 125 | 110 |

| RTFT-V11, RTFT-V12 | Flush Sliding Trolley | 100 | 100 | 100 | 100 |

| RTFP-QRV75, RTFP-QRV75-BRK, RTFP-QRV100, RTFP-QRV100-BRK, RTFP-QRV12, RTFP-QRV12-BRK |

Flush Rotating Quick Release Positioner | 125 | 125 | 125 | 110 |

| RTFT-QRV75, RTFT-QRV75-BRK, RTFT-QRV100, RTFT-QRV100-BRK, RTFT-QTV12, RTFT-QRV12-BRK |

Flush Rotating Quick Release Sliding Trolley | 100 | 100 | 100 | 100 |

| RTFP-ST632 | Flush Tilting Quick Release Positioner | 100 | 100 | 100 | 100 |

| RTFT-ST32 | Flush Tilting Quick Release Sliding Trolley | 100 | 100 | 100 | 100 |

Appendix B: Documentation Required for Calculating Payload Capacities for MKIT-M2 and MKIT-N2

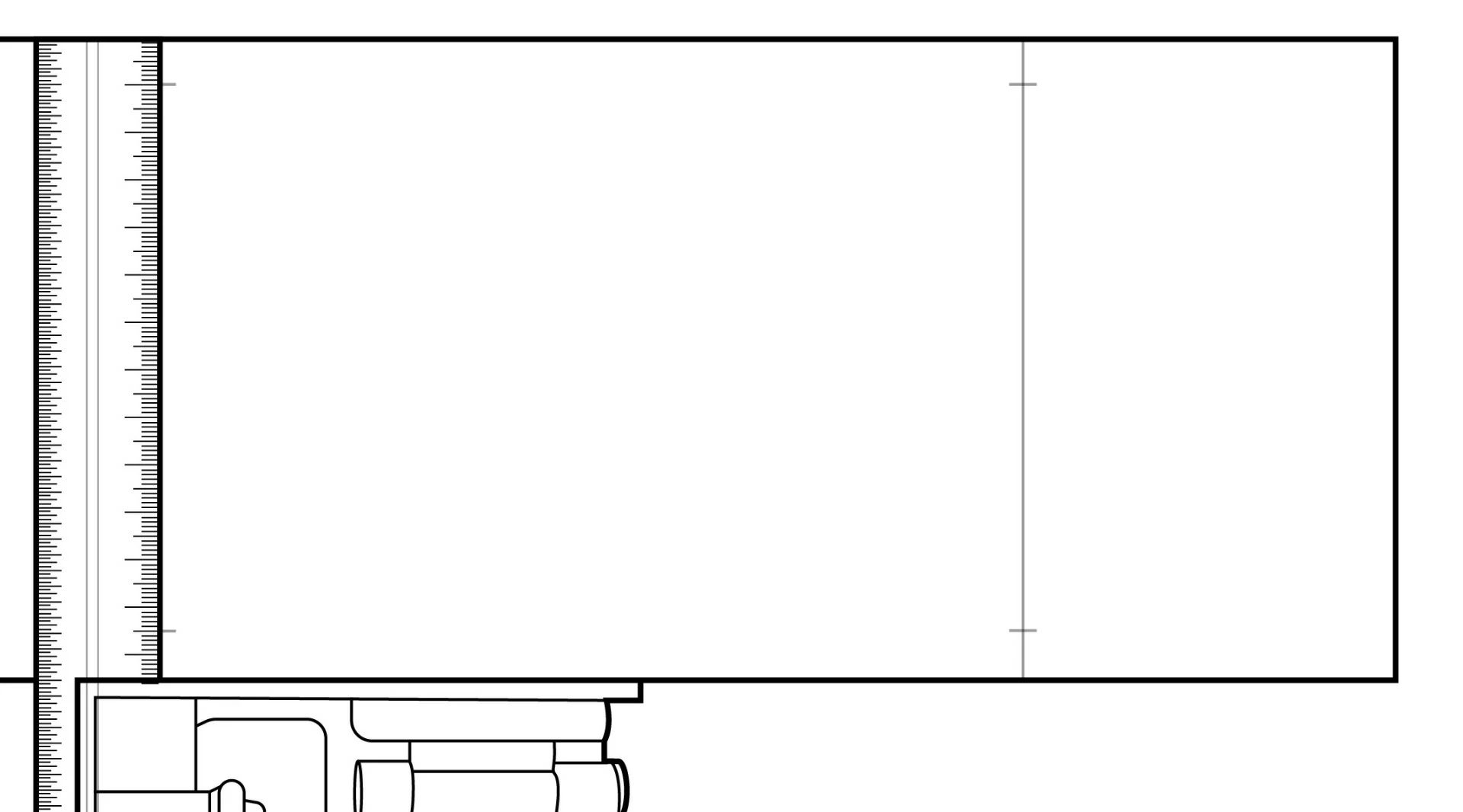

When multiple devices share one track, each mount should be listed separately with its components and payload description. The minimal distances between carriages and devices must also be documented so a comprehensive payload analysis can be conducted by Ergomart. A hand sketch, at minimum, of the below products and values is required for a full analysis.

FAQs

Q: Why do I have to put mounting holes along the bottom flange of the track when all the pull out stress is clearly along the top flange? A: Matching holes patterns on top and bottom are a default prescription to create visual symmetry and so not technically required in almost all applications. Contact Ergomart for assistance in determining the minimum necessary fastening points along the bottom flange for your installation.

Q: I want to hang the RT1 track upside down from the ceiling, do you have a solution? A: Yes, contact Ergomart and we will provide guidance and assistance to meet your requirement.